Monitoring of Explosive Gas Concentrations

Dust Detection

In some cases, solid or liquid dust particles can pose an explosion hazard. Dust sensors can detect their presence in the environment and trigger alarms if concentrations exceed safe levels.

Ventilation Monitoring

W instalacjach biogazowych, które wytwarzają metan z Effective ventilation is critical in explosion hazard zones to prevent the accumulation of potentially dangerous gases or dust. Monitoring systems can assist in controlling the effectiveness of ventilation systems. organicznych materiałów, metanomierze są stosowane do monitorowania produkcji biogazu i kontrolowania procesów produkcji.

Dust Concentration Measurement

Air Quality Monitoring

Dust concentration measurements are essential for monitoring air quality to assess public health. Suspended particulates, such as PM2.5 (particles smaller than 2.5 micrometers) and PM10 (particles smaller than 10 micrometers), can affect human health and the environment. Dust measurements are used in air quality monitoring in urban and industrial areas.

Workplace Safety

In workplaces where dust-generating processes occur, dust concentration measurements are important for ensuring employee safety. Exposure to high dust concentrations can lead to health issues, such as respiratory diseases.

Pollution Emission Monitoring

In industrial facilities like power plants, material processing plants, or recycling plants, dust concentration measurements are used to monitor pollution emissions and ensure compliance with regulatory requirements.

Product Quality Control

In some industries, such as pharmaceuticals or food production, product quality control may include dust concentration measurements as part of the production process.

Explosion-Proof Power Supply for Ten Telephone Lines

Telecommunications in Hazardous Environments

In areas where there is a risk of explosive gases or dusts (e.g., chemical, oil, or mining industries), an explosion-proof power supply is essential to ensure the continuity of telecommunications services. It ensures that the power supply to telephone lines does not become a potential source of sparks or ignition.

Signal Amplification in Remote Locations

Explosion-proof power supplies can be used in areas where access to traditional electrical power is limited or unsafe. These systems provide the necessary energy for reliable communication in challenging environments.

Emergency Telecommunications

In case of power outages, explosion-proof power supplies can serve as backup power for telephone lines, ensuring communication continuity in emergency situations.

Monitoring and Control Systems

For monitoring and control systems that use telephone lines to transmit data, an explosion-proof power supply is critical to ensure the reliability and safety of data transmission.

Communication in Environments Sensitive to Electromagnetic Interference

In areas where electromagnetic interference may negatively impact the quality of telecommunication signals, an explosion-proof power supply can help minimize these disturbances and ensure stable communication.

Safety and Technological Parameter Monitoring Systems

Workplace Safety

In workplaces where dust-generating processes occur, monitoring dust concentration is crucial for ensuring the safety of workers. Exposure to high dust concentrations can lead to health issues, such as respiratory diseases. These systems help in detecting unsafe levels of dust, providing early warning signals to prevent health risks.

Monitoring Product Quality Parameters

In manufacturing processes, monitoring the quality parameters of products, such as dimensions, chemical composition, or performance, is essential. These systems ensure consistency and high quality in production, helping to meet industry standards and customer expectations. By continuously tracking and controlling these parameters, manufacturers can optimize production efficiency and reduce defects.

Stress Determination in Rock Mass and Its Temporal and Spatial Changes

Tunnel Design and Construction

When designing and building tunnels, determining the stresses in the rock mass is critical to selecting appropriate drilling techniques and tunnel stabilization methods. Monitoring stress changes during the construction process is essential for maintaining safety and ensuring work efficiency. This helps prevent tunnel collapse and guarantees structural integrity throughout the project.

Hydrotechnics

In hydrotechnics, monitoring the stresses in the rock mass is crucial during the construction of dams and weirs. It helps assess the impact of groundwater pressures and stress changes on the structure, ensuring its durability and stability over time.

Geotechnics

In geotechnics, determining stress in the rock mass is important for construction projects such as foundations, bridge supports, and other structures. Continuous monitoring of stress changes allows early detection of potential issues, which is vital for maintaining structural safety and performance.

Seismic Research

In seismic research, monitoring stresses in the rock mass is essential for analyzing rock behavior during earthquakes. This data is used to assess seismic risks, improve building resilience, and better understand geological hazards.

Energy Resources

In energy resource extraction, such as oil and natural gas, monitoring stress in the rock mass is crucial for evaluating and controlling the stability of drilling operations and wellbore integrity. This ensures safe and efficient extraction processes, preventing incidents related to well collapse or blowouts.

Workplace Safety

In workplaces where dust-generating processes occur, monitoring dust concentration is vital for protecting workers’ health. High dust concentrations can cause respiratory issues and other health problems, making dust monitoring an essential aspect of workplace safety management.

Measurement of Methane Concentrations

Air Quality Control

In industries where emissions of pollutants are often significant, air quality monitoring is essential to ensure compliance with environmental regulations and minimize the impact on the environment and workers’ health.

Fermentation Control

In biogas plants that produce methane from organic materials, methane analyzers are used to monitor biogas production and control production processes.

Geological Studies

In geological research, methane analyzers can be used to detect the presence of methane in rocks and sediments to assess the potential of natural gas reserves.

Air Quality Control

In industries where emissions of pollutants are often significant, air quality monitoring is essential to ensure compliance with environmental regulations and minimize the impact on the environment and workers’ health.

Monitoring of Gas Content in the Air in Industrial Plants

Air Quality Monitoring

Airborne dust concentration measurements are crucial for monitoring air quality to assess public health. Suspended particles, such as PM2.5 (particles smaller than 2.5 micrometers) and PM10 (particles smaller than 10 micrometers), can impact human health and the environment. Dust measurements are used in air quality monitoring in cities and industrial areas.

Monitoring of Production Processes

In the manufacturing industry, particularly in chemical production or material processing, such devices can assist in monitoring processes and maintaining product quality by controlling the concentration of specific gases during production.

Industrial Process Automation

The device can be used to automate industrial processes based on continuous gas measurements. With two digital signal outputs, it is possible to control processes in real time depending on measurement results.

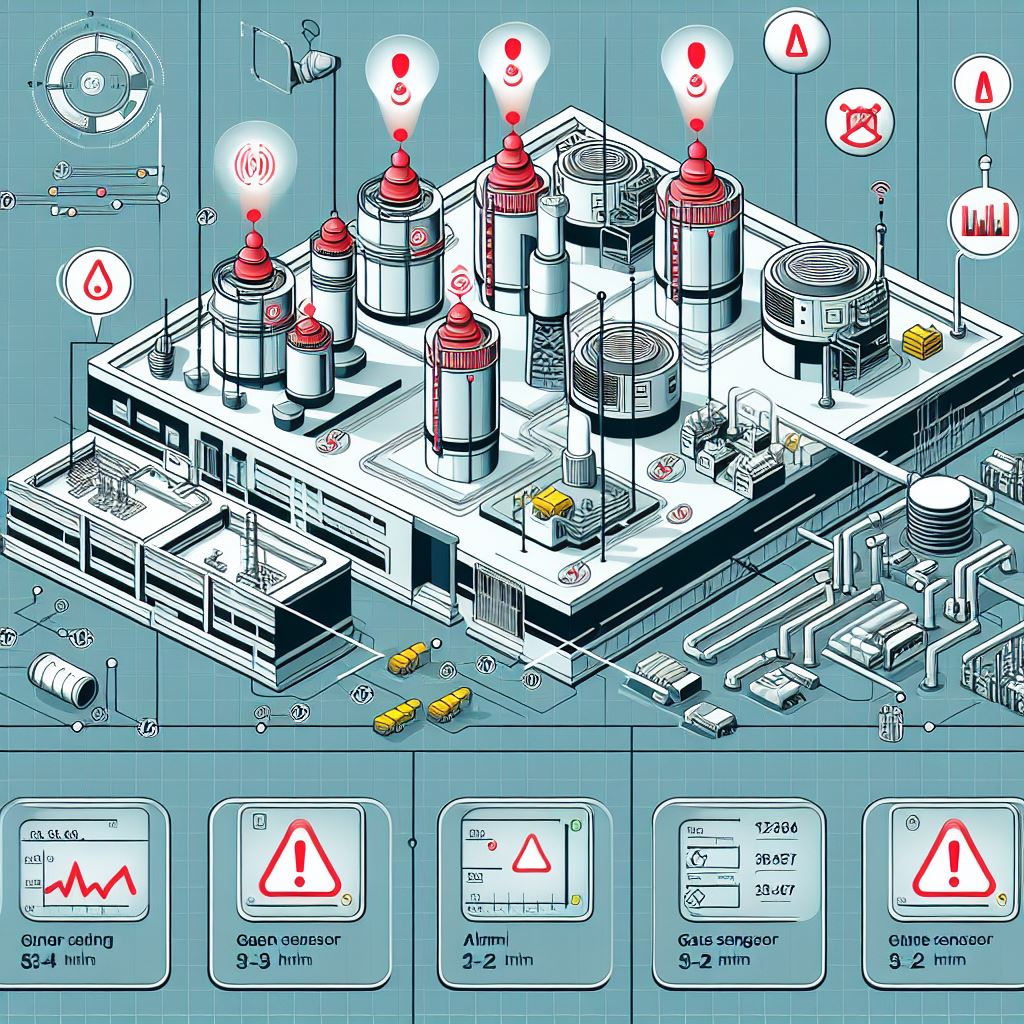

Alarm and Warning Systems

The two digital signal outputs enable the activation of alarms when specific gas levels or concentrations are exceeded, which is important in safety and warning systems.

Ground or Structural Vibration Monitoring

Civil Engineering

Vibration monitoring is important during the construction of new buildings, such as bridges, towers, buildings, or tunnels. It helps to determine if vibrations generated by heavy construction equipment or explosives affect the stability of structures and the quality of the work.

Exploration and Identification of Geological Deposits

Exploration and identification of geological deposits is the process of identifying, studying, and assessing potential mineral resources or geological materials in a given area. This process is crucial for the mining industry and can include various stages and techniques.

Geological Modeling

Geological Analysis: Geologists conduct a detailed analysis of the area’s geology, studying the type of rocks, their structure, mineral composition, and geological history. This analysis can help identify potential deposit locations.

Safety and Environmental Protection

Vibration monitoring can be used to assess the impact of vibrations on human comfort and safety, especially in workplaces or residential areas near vibration sources.

Explosion-proof Power Supply for Electrical Devices Underground

Process Control and Monitoring Systems

In the chemical or petrochemical industries, where potentially hazardous substances are present, explosion-proof power supplies are essential to power process control and monitoring systems, ensuring safe and reliable operation.

Safety and Alarm Systems

In workplaces with explosion risks, such as coal power plants or chemical plants, explosion-proof power supplies are used to power alarm systems, fire suppression systems, and other safety measures.

Telecommunication Systems

On drilling platforms or in mining, explosion-proof power supplies are necessary to power telecommunication systems, which are vital for communication and operation management.

Measurement Systems

In environments where monitoring and measurement of technical or environmental parameters, such as gas concentrations or humidity, are required, explosion-proof power supplies are used to power sensors and measurement systems.

Interested in Collaboration?

Feel free to reach out.

If you have any questions about our services or products, we invite you to get in touch.

Products

AS-3ES

The AS-3ES anemometer is designed for continuous measurement of air flow velocity in mine tunnels, shafts, corridors, and for signaling the loss of airflow according to a preset alarm threshold. Connected to an alphanumeric display, it enables hazard signaling at the entry into the controlled area.

AS-4ES

DAV

The DAV anemometer is an advanced device designed for continuous air flow velocity measurement in mine tunnels, shafts, corridors, and for local signaling of airflow loss. The high-brightness optical element signals hazards at the entry into a controlled area. The measurement head can be placed up to 30 meters away from the base unit.

MM4-XRS, D**-XRS

DXX

MM-2PW

The MM-2PW methanometer is designed for continuous methane concentration monitoring within the range of 0-100% CH4. It is tailored for measurement of methane concentration: In mining atmospheres (MM-2PW model); In pipelines (MM-2PW/A model)

MM-4

MM-4XRS

DCH

Water Curtains: Functional and Aesthetic Solutions for Urban Landscapes

EnviroPulmoGuard

DustAir

DustAir is a portable dust meter that informs users about the air quality they are breathing, allowing them to take preventive actions when necessary. It is designed to be attached to a bag, backpack, bicycle, or belt, and provides real-time air pollution measurements wherever you are.

Dust Meter PŁ-3

PANTERA Vibration Recorder

The PANTERA digital vibration recorder is used to measure parasismic vibrations, such as those generated by blasting operations, within the frequency range of 1 Hz to 100 Hz. This device is designed to monitor ground vibrations or building structures in specific areas.

PASAT M

This portable seismic apparatus is designed for precise measurements in the field, with modular components that allow for flexible configuration based on specific needs. It is particularly useful for identifying geological irregularities, measuring physical and chemical properties of rocks and soil, and selecting optimal sites for sensor placement in exploratory geophysics.

MZT 10/60M

MCCD-01

KB-1 Keyboard

Intrinsically Safe Power Supply ZI2-24

The ZI2-24 intrinsically safe power supply is designed for the safe operation of electrical devices in areas prone to methane explosions, specifically in mining environments. It operates from a 230 VAC single-phase network and is intended for installation in non-hazardous areas such as control cabinets or surface enclosures.

ZIH2-12

The ZIH2-12/1 and ZIH2-12/1.7 intrinsically safe power supplies are designed for safely powering electrical devices in underground mines. The components are housed in flameproof enclosures, allowing them to operate in areas at risk of methane explosion.

V-BOX Intrinsically Safe Buffered Power Supply

ZI2-12 Intrinsically Safe Power Supply

Services

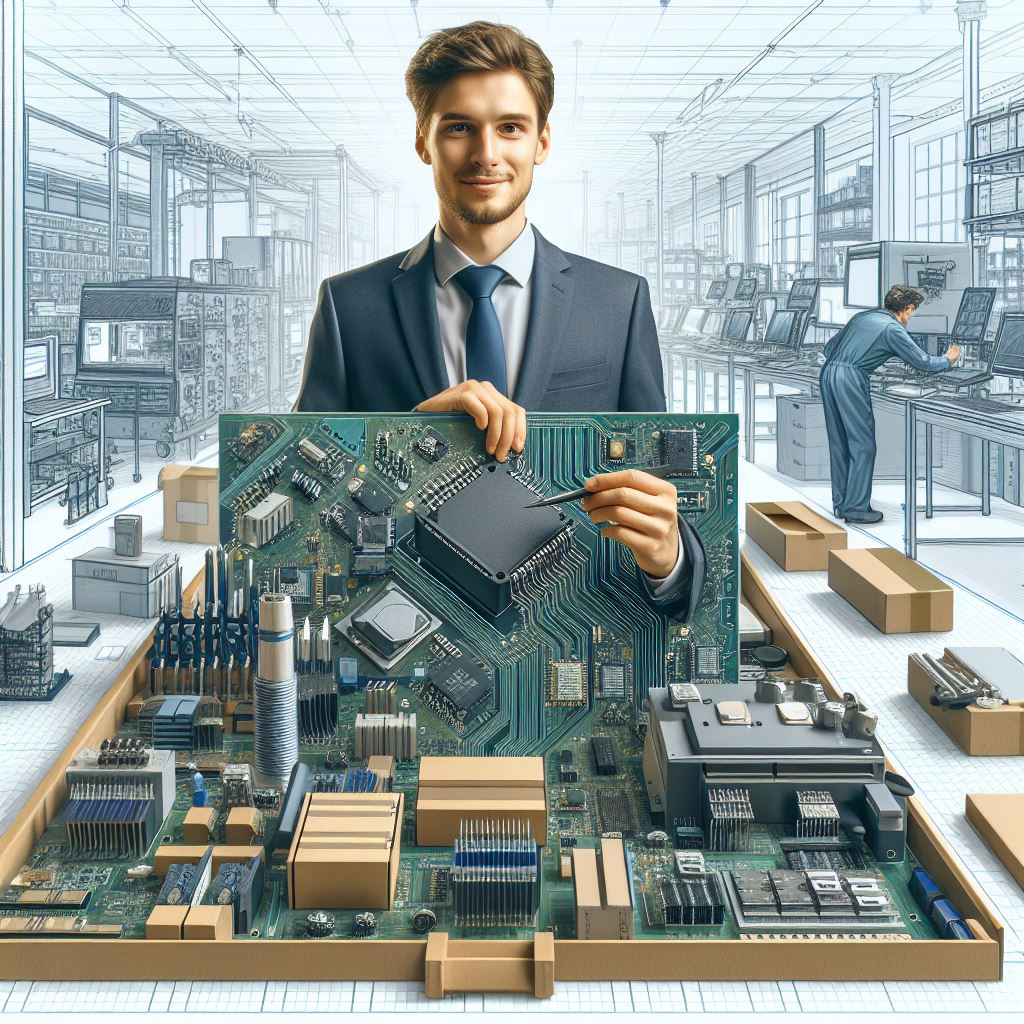

Assembly and Functional Testing

Our final assembly stations are designed to meet the individual needs of each client and the characteristics of their products. We use tools and equipment that guarantee error elimination and optimal material flow, resulting in the highest quality end product in contract electronics.

Electronics Production

Electronics production is an extremely complex process that involves multiple stages, each requiring precision, advanced technologies, and specialized knowledge. The manufacturing of electronic devices is based on the use of appropriate components, parts, and circuits to create efficient and functional equipment.

Mechanical Component Manufacturing

Mechanical component manufacturing is a process of producing precision mechanical components, often serving as key elements in larger systems, machines, or devices. The production process requires the use of advanced mechanical processing technologies such as turning, milling, grinding, and cutting.

Designing Solutions for Industrial Safety and Innovation

Design is the process of creating solutions, products, and services using engineering knowledge and advanced tools. It is a comprehensive and interdisciplinary field that covers both technical and user-centric aspects.

Interested in Collaboration?

Feel free to reach out.

If you have any questions about our services or products, we invite you to get in touch.