JUKI KE-3020L

The JUKI KE-3020L is an advanced Surface Mount Technology (SMT) machine used in the electronics industry for placing various components onto printed circuit boards (PCBs). It is widely utilized in the electronics sector for the production of a wide range of products, from mobile phones to computer equipment.

Key Benefits

High Precision Assembly: The JUKI KE-3020L is renowned for its excellent assembly precision, essential for placing microscopic components on small printed circuit boards (PCBs). Its precision enables the mounting of components in various sizes and shapes, including microprocessors, resistors, capacitors, integrated circuits, and BGA (Ball Grid Array) components, among others.

High Efficiency: The JUKI KE-3020L is a highly efficient machine, capable of handling large volumes of components in a short amount of time.

Versatility: This machine is capable of assembling various types of components, making it a versatile tool for SMT assembly. It can handle different component sizes and support various assembly types, including surface-mount technology (SMT) and through-hole technology (THT) assembly.

Advanced Software: The JUKI KE-3020L uses advanced software to manage the assembly process, ensuring optimal performance and precision throughout production.

AOI PARMI Xceed L

The PARMI Xceed-L Inline is a high-performance machine designed for PCB assembly and manufacturing, particularly suited for prototyping and small to medium-scale production. It can process up to 5,000 boards per hour, making it one of the fastest PCB assembly systems available on the market. With LED light sources, it ensures precise component placement, while its 3D vision capabilities allow users to visually inspect boards. The device can import data from CAD systems and generate component placement programs.

Key Benefits

Laser Scanning Line Method: Offers precise scanning of component placement, enhancing overall accuracy.

Industry’s Highest Inspection Speed: Capable of inspecting boards at an incredibly fast pace, improving overall production efficiency.

Color, Material, and Surface Roughness Independent Inspection: Allows for reliable inspection regardless of variations in color, material, or surface texture.

Inspection Up to 65mm Height: Provides inspection capabilities for taller components, expanding its versatility.

Inspection Without Additional Cycle Time: Ensures that the inspection process doesn’t slow down production, maintaining high throughput.

DOOSAN DNM 500

The DOOSAN DNM 500 is a vertical machining center used for cutting operations and is commonly employed in the manufacturing industry for processing metals and plastics.

Key Benefits

Vertical Machining Center: The DOOSAN DNM 500 features a vertical machining design, with tools approaching from above. The rotating table allows for machining of multiple sides of the part, making it ideal for producing complex components.

High Precision: This machine offers high machining accuracy, allowing for precise cutting, hole drilling, and milling on components of various shapes and sizes.

High Efficiency: Equipped with a powerful spindle and axis systems, the DOOSAN DNM 500 delivers efficient and fast processing operations, making it suitable for both serial production and single prototype work.

Advanced Control System: The DOOSAN DNM 500 is equipped with a state-of-the-art CNC (Computer Numerical Control) system that enables precise programming and control of machining processes. Operators can create, modify, and monitor machining programs in real-time for optimal productivity.

DZ-450 Apcom Dispenser

APCom dispensers are reliable devices that perform excellently in various applications.

Key Benefits

Mixing dispensing capacity: From 10 mL/min to 3 L/min.

Ingredients: From 1 to 4 ingredients.

Dispensing: Ability to dispense all ingredients simultaneously with a programmed ratio.

Configuration: Ability to configure, for example, 3 ingredients A (e.g., different colors) and one ingredient B, dispensing only 2 ingredients at a time.

Tanks: From 1 to 4 tanks, with the option to configure two tanks for one ingredient – useful for continuous operation.

Capacity: 10 L / 20 L / 40 L.

Dispensing accuracy: 1%.

Dispensing modes: Continuous or programmed doses.

Programmable parameters: Ratio, dose size, dispensing speed, and other useful parameters.

ERSA Hot Flow 2/12

The ERSA Hot Flow 2/12 is an advanced device designed for wave soldering processes. It is equipped with 12 independently controlled heating zones and 2 cooling zones, allowing for the configuration of the optimal soldering profile. It is highly regarded for its high-quality soldering and reliability.

Key Benefits

Wave soldering process: The ERSA Hot Flow 2/12 is designed for wave soldering, ensuring solid connections between components and PCBs.

High precision soldering: The ERSA Hot Flow 2/12 offers a very precise soldering process. The fine-tuned wave speed and temperature control ensure even solder distribution and minimize the risk of defective solder joints.

High efficiency: The ERSA Hot Flow 2/12 is a highly efficient machine capable of soldering multiple PCBs in a short time. With advanced feeding mechanisms, speed control, and temperature regulation, it is an ideal tool for mass production in the electronics industry.

Versatility: The ERSA Hot Flow 2/12 supports various types of PCBs and components, accommodating different sizes, component types, and solder types.

Advanced control system: The ERSA Hot Flow 2/12 is equipped with an advanced control system, allowing operators to precisely control the soldering process.

HAAS SUPER MINI MILL

The HAAS Super Mini Mill is an advanced CNC (Computer Numerical Control) milling machine used for machining in the manufacturing industry. It is commonly utilized for precise cutting, drilling, milling, and processing of various materials such as metal, plastics, and more.

Key Benefits

High Precision: HAAS offers very high machining precision. It is used to perform accurate cuts, milling, and drilling on parts of various shapes and sizes, ensuring quality and finish accuracy.

High Efficiency: The machine is equipped with a powerful spindle and axis systems, allowing for efficient and fast machining operations. This makes it suitable for both mass production and single prototype work.

Advanced CNC Controller: The machine features an advanced CNC controller that allows programming and control of the machining process. Our operators can create and modify machining programs and also monitor work progress in real-time.

AP-800 PCBA Coating Machine

The AP-800 is a versatile platform designed for precise material dispensing, making it a valuable tool across various industries and manufacturing processes.

Key Benefits

Precise Dispensing of Two-Component Materials: The AP-800 can accurately dispense two-component materials such as resins, allowing for the configuration of mixing ratios over a wide range, which is crucial for many manufacturing processes.

Use in Dispensing Various Substances: The machine can be used for dispensing adhesives, pastes, sealants, oils, and other substances, increasing production flexibility and capabilities.

Selective Coating Application: It allows for the selective application of coatings such as lacquer or other materials onto electronic circuits, providing precise and efficient coverage of specific areas.

Dispensing Accuracy: The AP-800 ensures dispensing accuracy of ±1%.

Continuous or Programmed Dose Dispensing Options: The flexibility to choose between continuous or programmed dosing enables customization for specific applications.

Precise Small Quantity Dispensing: The ability to dispense very small quantities of materials (minimum dose 0.5 ml) is crucial for applications requiring high precision.

Wide Viscosity Range: The machine handles a broad range of material viscosities (from 20 to 50,000 mPas), making it suitable for various substances with different properties.

Programmable Mixing Ratio Range: The programmable mixing ratio range allows the machine to be tailored to specific production requirements.

PMS 270/350 HAD

The PMS 270/350 HAD is a semi-automatic saw designed for cutting closed materials, profiles, and pipes at both right angles and various angles (up to 60° on one side and up to 45° on the other side).

Key Benefits

Increased Cutting Efficiency: The PMS 270/350 HAD significantly improves cutting efficiency. The saw features an integrated semi-automatic cycle, which includes hydraulic control for lifting and lowering the arm, as well as a hydraulically controlled solid vice.

Versatile Cutting Capabilities: The saw is capable of cutting profiles and alloy steels of various shapes with a maximum thickness of 1mm, including closed materials up to a diameter of 270mm.

Angular Cutting: The machine allows for angular cutting of materials on both sides, offering flexibility in various applications.

PUMA 1500SY

The PUMA 1500SY is an advanced CNC (Computer Numerical Control) turning and milling machine used in the manufacturing industry for processing parts. It is equipped with a system that integrates rotary spindles, allowing both turning and milling operations to be performed on the same machine.

Key Benefits

Turning and Milling with Rotary Spindles: The PUMA 1500SY is equipped with two rotary spindles that allow for turning and milling operations on the same machine, providing flexibility and efficiency in part production.

High Precision Machining: The PUMA 1500SY offers very high precision in machining. It can perform precise turning, milling, drilling, threading, and other operations on various materials, including metals, plastics, and ceramics.

High Productivity: The PUMA 1500SY is equipped with powerful spindles and axis systems, enabling both serial production and the ability to work with single prototypes.

Advanced CNC Controller: The PUMA 1500SY features an advanced CNC controller that allows for programming and controlling the machining process. Operators can create and modify machining programs and monitor the progress of work using an intuitive user interface.

PUMA 2600SY

The PUMA 2600SY is an advanced CNC (Computer Numerical Control) turning and milling machine commonly used in the manufacturing industry for processing precision parts. It is known for its high-quality machining, great precision, and multifunctionality.

Key Benefits

High Precision Machining: The PUMA 2600SY offers extremely high precision. It can perform accurate turning, milling, drilling, and threading operations on various materials, including metals and plastics.

High Productivity: The PUMA 2600SY is equipped with powerful spindles and axis systems, enabling efficient and rapid machining. This makes it suitable for both serial production and single prototype work.

Advanced CNC Controller: The machine features an advanced CNC controller, allowing for the programming and control of the machining process. Operators can create and modify machining programs and continuously monitor the progress of work.

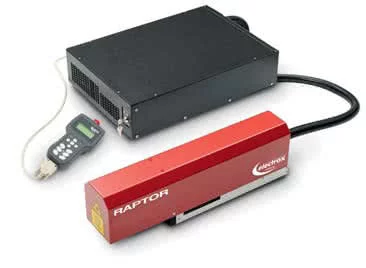

Laser Engraver Raptor II

The Raptor II laser engraver is an advanced marking device that utilizes laser technology for permanent marking of items, materials, and surfaces.

Key Benefits

Laser Technology: The Raptor II uses a laser beam to remove material or create permanent markings on various surfaces. Laser technology enables precise and durable markings that are resistant to wear and corrosion.

High Precision: The Raptor II offers very high precision, which is particularly important for small and complex details. It can mark various materials, such as metals, plastics, glass, ceramics, rubber, and more.

Various Marking Types: The Raptor II allows for various types of marking, including engraving, text marking, serial numbers, QR codes, barcodes, and other graphics.

Contactless Marking: Laser marking is contactless, meaning it does not require physical contact with the surface. This helps avoid material damage and maintains a high-quality finish.

Speed and Efficiency: The Raptor II is equipped with powerful and fast lasers, allowing for marking in a relatively short time. It is ideal for serial production and manufacturing processes that require marking.

Super Swash Automatic Washing System

SuperSwash is a versatile cleaning system designed for washing PCBs with components, stencils, squeegees, and mechanical parts.

Key Benefits

Removes all types of soldering contaminants.

Cleans micro-mechanical parts.

Cleans contaminants from the printed circuit board (PCB) manufacturing process.

Cleans PCBs with components such as BGA, CSP, BTC, QFN, and MELF.

Prepares PCBs for coating or protective layer application.

Products

AS-3ES

The AS-3ES anemometer is designed for continuous measurement of air flow velocity in mine tunnels, shafts, corridors, and for signaling the loss of airflow according to a preset alarm threshold. Connected to an alphanumeric display, it enables hazard signaling at the entry into the controlled area.

AS-4ES

DAV

The DAV anemometer is an advanced device designed for continuous air flow velocity measurement in mine tunnels, shafts, corridors, and for local signaling of airflow loss. The high-brightness optical element signals hazards at the entry into a controlled area. The measurement head can be placed up to 30 meters away from the base unit.

MM4-XRS, D**-XRS

DXX

MM-2PW

The MM-2PW methanometer is designed for continuous methane concentration monitoring within the range of 0-100% CH4. It is tailored for measurement of methane concentration: In mining atmospheres (MM-2PW model); In pipelines (MM-2PW/A model)

MM-4

MM-4XRS

DCH

Water Curtains: Functional and Aesthetic Solutions for Urban Landscapes

EnviroPulmoGuard

DustAir

DustAir is a portable dust meter that informs users about the air quality they are breathing, allowing them to take preventive actions when necessary. It is designed to be attached to a bag, backpack, bicycle, or belt, and provides real-time air pollution measurements wherever you are.

Dust Meter PŁ-3

PANTERA Vibration Recorder

The PANTERA digital vibration recorder is used to measure parasismic vibrations, such as those generated by blasting operations, within the frequency range of 1 Hz to 100 Hz. This device is designed to monitor ground vibrations or building structures in specific areas.

PASAT M

This portable seismic apparatus is designed for precise measurements in the field, with modular components that allow for flexible configuration based on specific needs. It is particularly useful for identifying geological irregularities, measuring physical and chemical properties of rocks and soil, and selecting optimal sites for sensor placement in exploratory geophysics.

MZT 10/60M

MCCD-01

KB-1 Keyboard

Intrinsically Safe Power Supply ZI2-24

The ZI2-24 intrinsically safe power supply is designed for the safe operation of electrical devices in areas prone to methane explosions, specifically in mining environments. It operates from a 230 VAC single-phase network and is intended for installation in non-hazardous areas such as control cabinets or surface enclosures.

ZIH2-12

The ZIH2-12/1 and ZIH2-12/1.7 intrinsically safe power supplies are designed for safely powering electrical devices in underground mines. The components are housed in flameproof enclosures, allowing them to operate in areas at risk of methane explosion.

V-BOX Intrinsically Safe Buffered Power Supply

ZI2-12 Intrinsically Safe Power Supply

Services

Assembly and Functional Testing

Our final assembly stations are designed to meet the individual needs of each client and the characteristics of their products. We use tools and equipment that guarantee error elimination and optimal material flow, resulting in the highest quality end product in contract electronics.

Electronics Production

Electronics production is an extremely complex process that involves multiple stages, each requiring precision, advanced technologies, and specialized knowledge. The manufacturing of electronic devices is based on the use of appropriate components, parts, and circuits to create efficient and functional equipment.

Mechanical Component Manufacturing

Mechanical component manufacturing is a process of producing precision mechanical components, often serving as key elements in larger systems, machines, or devices. The production process requires the use of advanced mechanical processing technologies such as turning, milling, grinding, and cutting.

Designing Solutions for Industrial Safety and Innovation

Design is the process of creating solutions, products, and services using engineering knowledge and advanced tools. It is a comprehensive and interdisciplinary field that covers both technical and user-centric aspects.

Interested in Collaboration?

Feel free to reach out.

If you have any questions about our services or products, we invite you to get in touch.